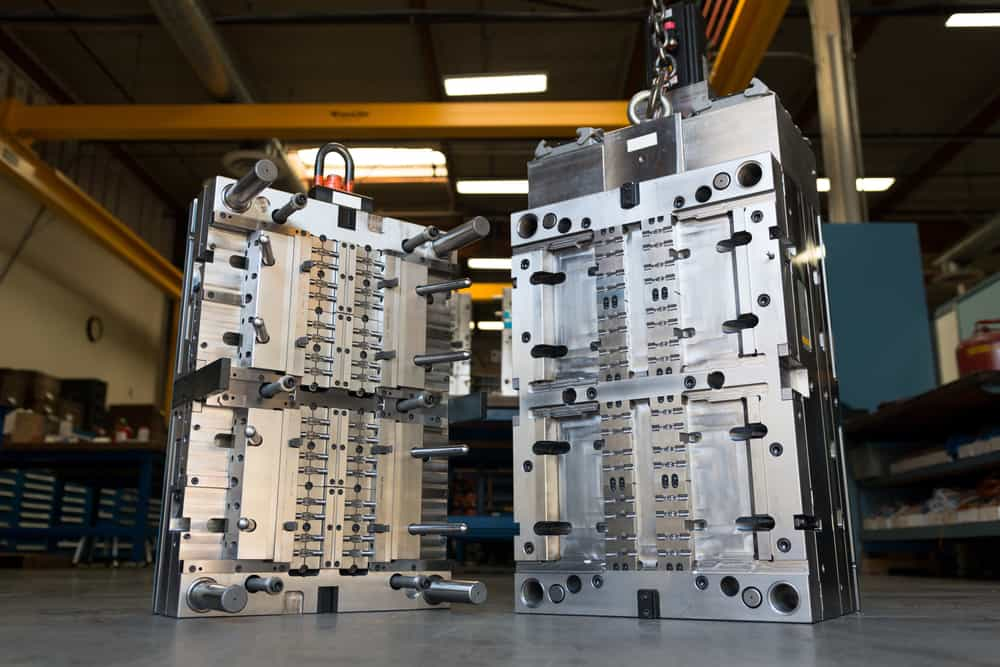

One key procedure when it comes to the efficient production of the plastics industry parts is injection molding. This makes it But did you know that there is a way to improve further the functionality and appearance of the injection molding process result? This is through the use of mold surface textures (mold texturing).

With the help of mold texturing, you get to improve the durability, look, and strength of the resulting product. Mold surface textures also add patterns to it. This article will give you more information about mold cavity and surface textures and their importance in injection molding, so you can increase your knowledge about this process.

What is Surface Texture?

When it comes to injection molding, one common term that you can connect to is mold cavity or surface texture. It basically refers to the unique and distinctive qualities and characteristics of mold surfaces designed intentionally to affect the molded plastic parts’ feel, look, and overall functionality.

There are different techniques that you can use in creating mold surface textures. They are useful in attaining your preferred surface finish, whether it’s smooth, textured, patterned, glossy, or matte. What’s great about this surface texture is that it improves the product aesthetics as well as its slip- or grip-resistance, thereby helping the release of the mold tech partially and concealing flaws and imperfections.

Purpose of Mold Texturing

One primary purpose of mold texturing is to shape the feel and look of the final product. It also improves its overall performance and functionality. In the manufacturing industry, you can expect mold textures to describe surface textures of an object representing its surface’s three-dimensional shape.

The truth, though, is that only a few of these surfaces are fully featureless or flat. In other words, each surface holds a kind of mold tech texture, which demonstrates repeating and regular patterns at times. There are also instances when the textures are relatively random, so it is quite hard to generalize them effortlessly.

The main premise behind texturing is to form a set of patterns on the product’s surface. The fact that it has a direct effect on the performance and look of the product makes it important in injection molding. It is also a vital element in manufacturing and tooling design.

Different Types of Mold Surface Textures

Now that you have an idea about surface textures and the mold texturing process, it is time to familiarize yourself with the different types of mold surface textures. The following are the most common and effective ones that are applicable for injection molding and can produce your preferred effects.

Finishes Created by Polishing

As far as injection molding surface treatments and finishes are concerned, the ones created by polishing belong to Category A. They represent top-notch quality and lustrous and shiny results. To get this texture, you have to use a rotary tool, which can assure you of meticulous polishing.

This also executes the polishing action in a non-linear and random manner. This leads to a surface that has no discernible directionality. It also results in a more uniform pattern no matter what the viewing angle is.

Finishes Made by Sandpaper

This type of surface finish belongs to Category B. You can create this mold tech texture with a methodical sanding process that you have to do back and forth. The result would be linear scratches that also feature noticeable patterns.

A lot of manufacturers describe the finishes made by sandpaper as semi-gloss. It is actually a cost-effective substitute for polishing and has the ability to hide mold defects efficiently. For this surface finish, you will have to employ a sandpaper grit that is around 320 to 600.

Finishes Made by Grit Stone

You can create these mold surface textures with the help of grit standing stones that have grit sizes of around 320 to 600 – the same as sandpaper finishes. Note, though, that the textures you can get from grit stones have rougher surfaces compared to the others.

You will also notice less uniformity in the surfaces. This surface treatment demonstrate a matte finish. In addition, it works effectively in getting rid of tooling marks or mold tech flaws. Many also prefer it because of its guaranteed speed, which is also a good thing in preventing significant tooling expense.

Finishes Made by Blasting

Falling under Category D, this type features a rough surface finish, specifically rougher compared to the others as it results from abrasive blasting. This specific texturing procedure often uses sand or glass beads for its material.

The procedure involves spraying and blasting uniformly and randomly, thereby forming a surface finish without any directional patterns. What’s great about blasted mold textures is that they play a major role in creating subdued and flat finishes.

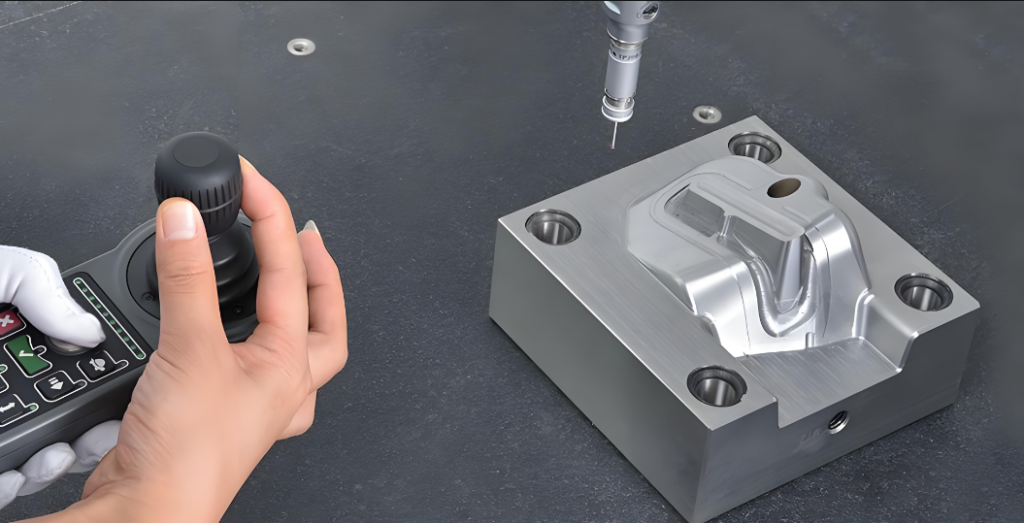

Finishes Made with EDM

There are also finishes made from Electronic Discharge Machining (EDM). This type creates mold surface finishes that resemble spark erosion. You can choose this approach based on the mold material that requires processing and its specific feature/s.

SPI Surface Finish Standard

If you are still unfamiliar with the SPI surface finish, then note that it is the standard that the Society of the Plastics Industry (SPI) has set for American surface finishes. Note, though, that this standard is not solely for America as it is also used globally.

As a matter of fact, industrial designers, mold makers, and marketers in different parts of the world use it. To give you an idea, here are the usual standards for SPI surface finish.

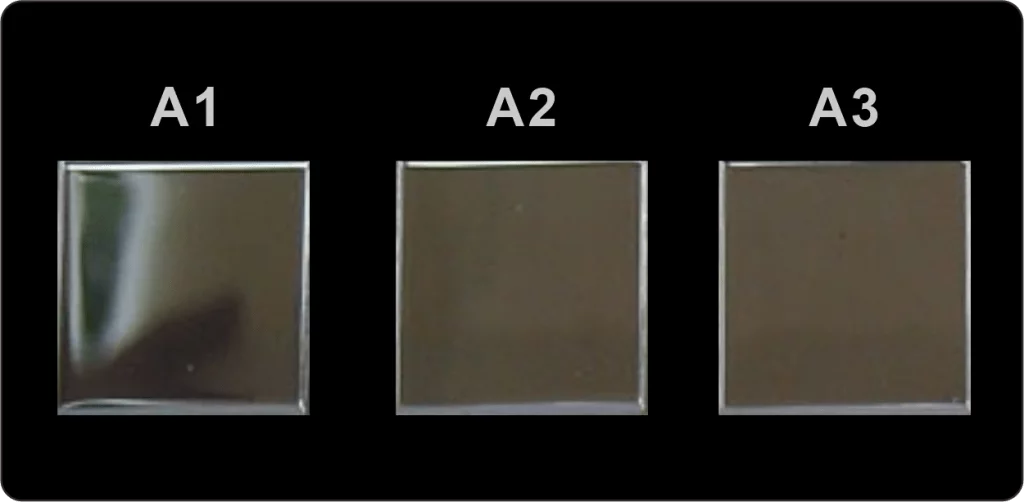

Shiny Finish

Falling under this category are finishes that have A in their SPI grades. To be more specific, they are labeled as A-1, A-2, and A-3. Such SPI surface finish grades display high gloss finishes, specifically applied to hardened steel molds.

-

A-1 – considered as the shiniest of all

-

A-2 – still so shiny but lower in grade than A-1

-

A-3 – shiny but with its gloss slightly reduced

The manufacturers here do the polishing or buffing of the steel molds surface with the help of fine diamond powder that has to be suspended in oil. Imagine visors and plastic mirrors when you think of the shiny surface finish.

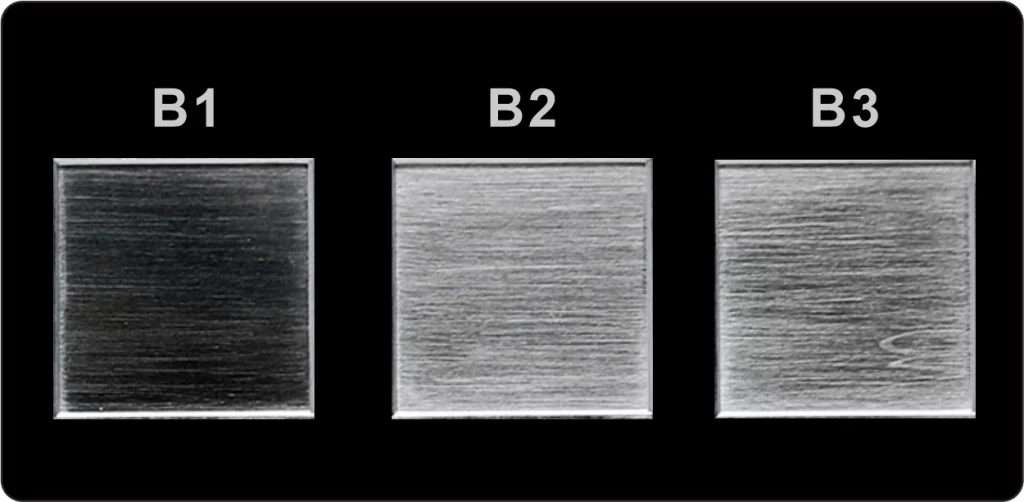

Semi-Gloss Finish

This is the perfect choice if you want the finish to have a slight shine but not a full gloss. Falling under the semi-gloss finish are the following classifications:

-

B-1 – highest semi-gloss

-

B-2 – medium semi-gloss

-

B-3 – lowest semi-gloss, though, you can still see it having a bit of sheen

In most cases, this surface is created with the aid of ultra-fine grit sandpaper. It works perfectly when trying to conceal minor defects in injection molding.

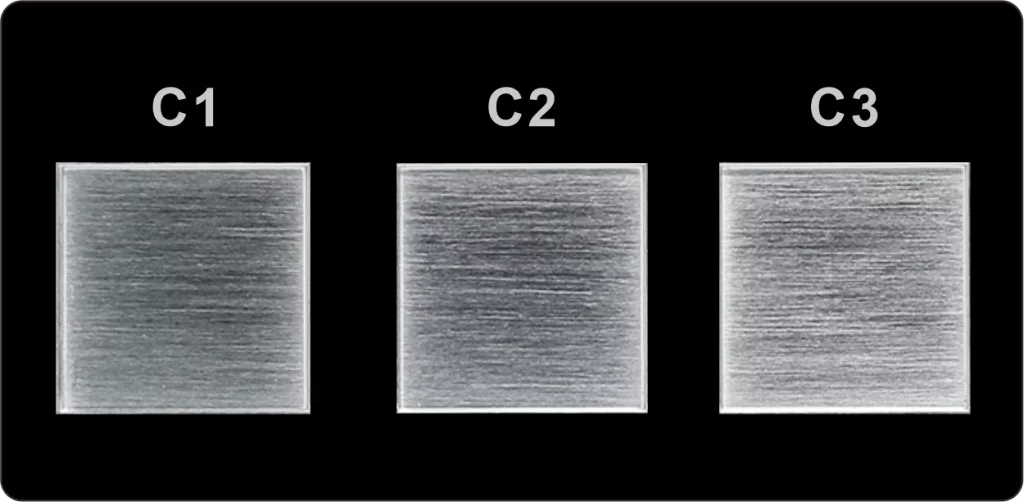

Matte Finish

This type of surface finish does not have any shine at all. What you can expect to see in the matte finish is a non-reflective and flat surface. Here are its classifications based on the level of matte finish:

-

C-1 – Smoothest

-

C-2 – Medium

-

C-3 – Roughest

To get such looks, any experienced plastic mold manufacturer will have to utilize fine stone powders. This surface finish works ideally for industrial components or parts.

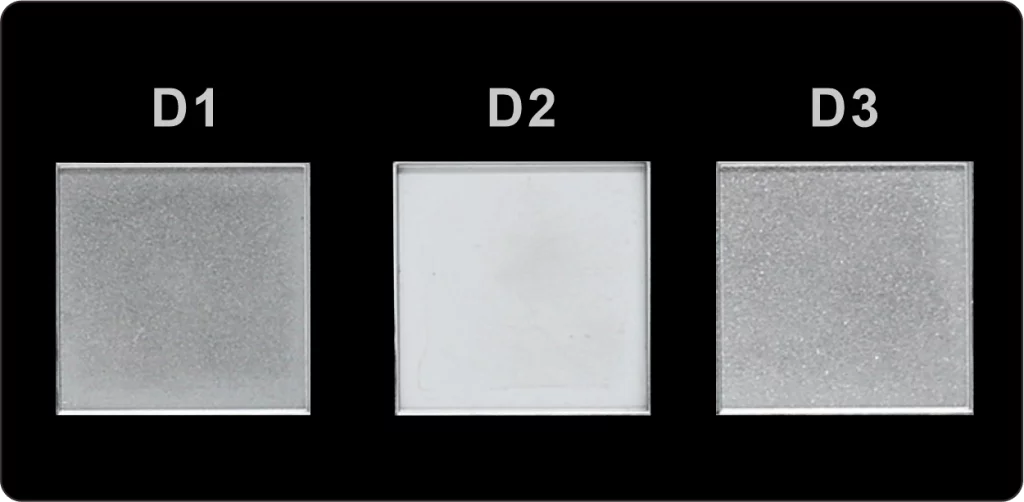

Textured Finish

The textured injection mold finish is the best choice if you want the surface to have a bit of grip. The following levels of mold tech texture can help you understand the classifications of textured mold finish even better.

-

D-1 – finest

-

D-2 – medium

-

D-3 – roughest

Advantages of Molded Surface Textures

Makes your product look better

Overall, molded surface textures are capable of improving the look of the end product. It is even easy for these textures to mask flaws and imperfections. Expect them to work effectively in camouflaging flow lines, burn marks, and sinks, among many other injection molding defects. It also leads to clean mold cavity.

Gets rid of flow creases in plastic material

The reason behind this is that the surface texture can add textured thickness to the product. Such textured molds can further strengthen the product, thereby eliminating any flow crease.

Improves grip

By incorporating molded surface texture into the product, you will notice its materials also improve their non-slip traits. This is a good thing as you will notice that plastic injection molded part being easier to hold than before. It can further result in the functionality and usability of the application plus it is also completely safe.

Improves adhesion and strength

Expect the molded surface texture to be a big help in withstanding contact damage once the product is in transit. It is also highly likely for the plastic injection molded part to withstand potential smudges coming from fingerprints.

The fact that the part is textured also makes it possible to be firmer in holding the paint. This is a good thing in increasing the number of molding operations you can do.