Your Global Partner for Quality Sensor Services in China

Shenzhen ZongHong Tech brings a wealth of experience from crafting thousands of custom shafts, ensuring your project benefits from high efficiency, precision, cost-effectiveness, and swift delivery.

- Over 40 Certified Materials

- Custom Finishes

- No Minimum Order

- Fast Turnaround

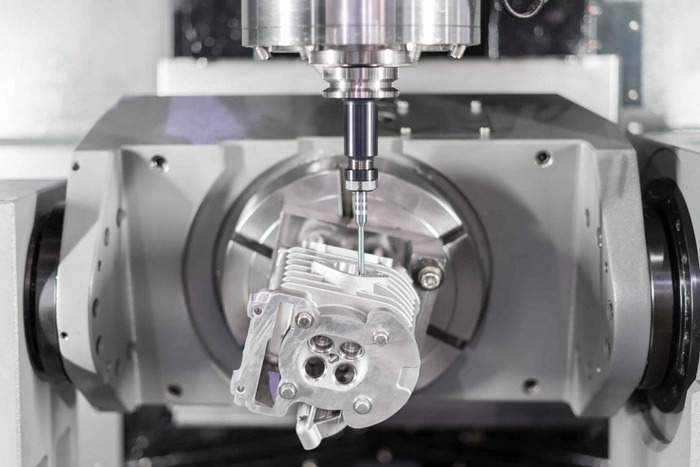

On-Demand CNC Machining Services

Shenzhen ZongHong Tech Co., Ltd., located in Shajing Town, Bao’an District, Shenzhen,China. Is a professional manufacturer specializing in the design and production of various fixtures, molds, non-standard parts, and equipment. The company utilizes advanced CAD and CAM technologies, possessing strong design and machining capabilities. The factory covers an area of over 5000 square meters.

-

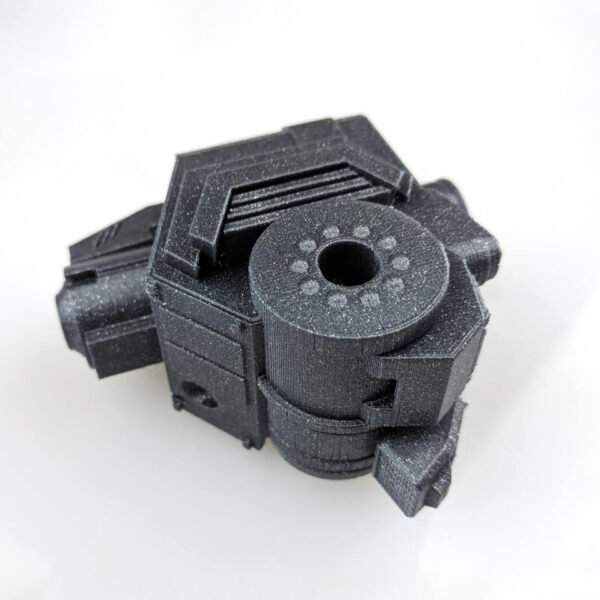

Rapid Prototyping 3D Printing

Read more -

Rapid Prototyping Vacuum Casting

Read more -

Rapid Prototyping Injection Mold

Read more -

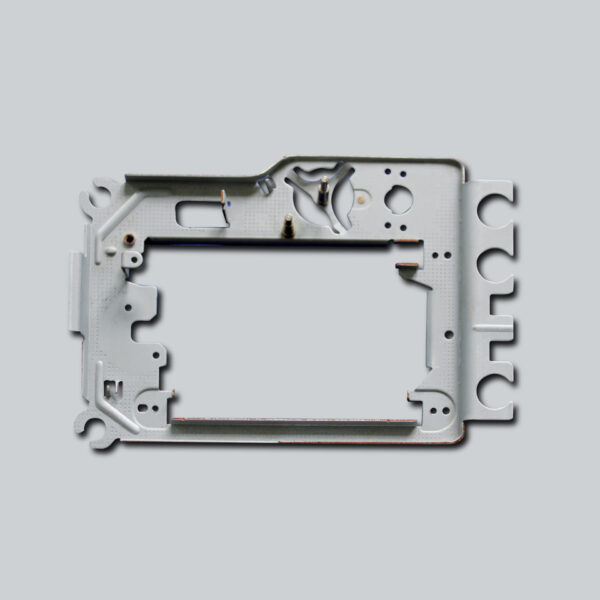

Rapid Prototyping Sheet Matel

Read more -

Rapid Prototyping Plastic

Read more -

Rapid Prototyping Matel

Read more -

3D Printing Photopolymer Resin

Read more -

3D Printing Matel

Read more

Start today. Get parts made fast.

Top China CNC Machining Services For Custom Parts

On-Demand CNC Machining Services

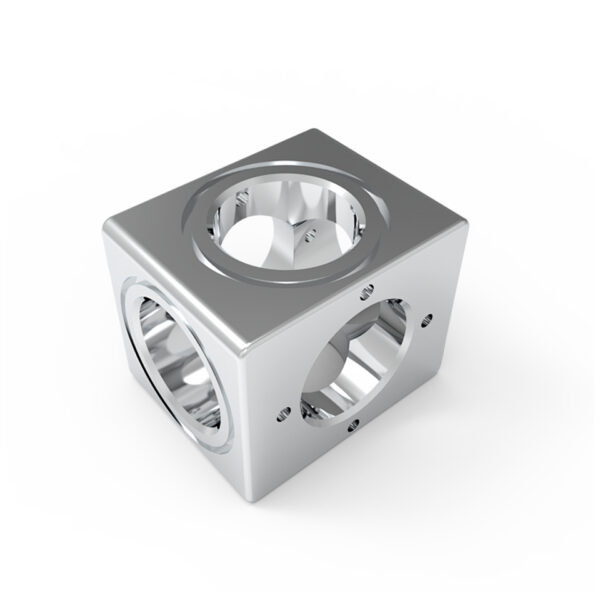

CNC Aluminium Machining parts

Pipe fitting

Auto Part

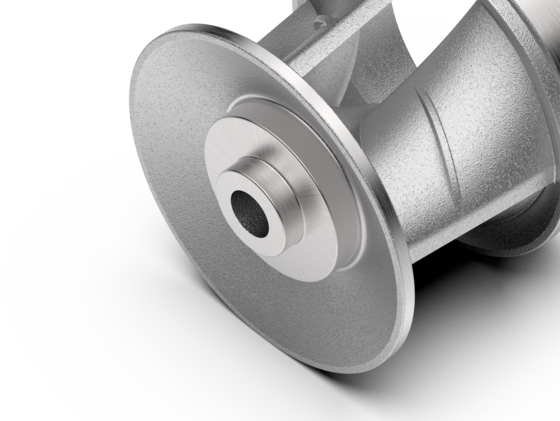

Investment casting parts

Perforation&Completion Tools

Customized parts

What makes Shenzhen ZongHong Tech Co., Ltd., Different?

ZongHong Tech has built its expertise in manufacturing CNC machined parts over the past 10 years.

As a custom CNC machining parts manufacturer, ZongHong Teck has diverse production sections and facilities to satisfy your various requirements and ever-growing demands.

You can always find the desired type of CNC parts online with our powerful production capacities.

60% better prices than the average market

80 % Percent Repeat Orders By Clients Procured Material from us

Dedicated Industry Expert assigned for each Project.

Solid after-sales customer support policy.

PRICE

DELIVERY TIME

SHIPPING COST

DESIGN COST

CUSTOMER RETENTION

RESPONSE TIME

How to Machining customized Shaft?

CNC Turning

CNC Milling

CNC Grinding

Heat Treatment

Surface Finishing

Our Service

High-Yield Manufacturing Services Across All Industries.

Aerospace & Defense

CNC Machining for Aerospace & Defense Parts

Automotive

Whatever your needs are in the automotive industry, whether it’s large engine block parts or smaller gears and panels, you’ve found a partner in Roberson Machine Company.

Food and Beverage

Companies in the food and beverage industry need a CNC machining company they can trust to make quality parts and equipment that are compliant with all industry standards and regulations. Roberson Machine Co. is that CNC machining company.

Packaging

The experienced team at Roberson Machine Company will help you develop just the right tool or machine for all of your packaging needs.

Medical

CNC machining at Roberson Machine Company is the perfect option for the medical industry, with precision manufactured parts and ongoing technological development in high demand.

Oil and Energy

Roberson Machine Company delivers high-grade CNC services for your top-of-the-line oil and energy industry parts and products.

OEM & Other Industries

Whatever industry you’re in, you need quality, durable, and precise parts for your customers. Roberson Machine Company’s advanced CNC machining allows us to manufacture any part or component you might need.

Why choose us

Quality

We guarantee each unit within a specified tolerance and use only the best materials.

Reliability

You can count on us to get the job done on time, right, every time, and for a price you can afford.

Precision

Precision machining that means you can pass along excellence to your customers.

Our Domestic And International Sales Market

ZongHong Teck has been a leading CNC machining company in China since 2016 thanks to its high-quality precision CNC machining services, robust production capabilities, fast delivery, and responsive engineering support 24/7.

Find custom precision CNC machining services for your plastic or metal parts and launch your projects faster with fewer risks and lower costs.

Versatile Facilities & Powerful Capabilities

CNC Milling Machines

CNC Lathe Machines

Modern Machining Workshop

ISO 9001 Certified Factor

Quality Testing Equipment

Aluminum CNC Machining Service

Frequently Asked Questions

CNC (Computer Numerical Control) services, also known as CNC machining services, are widely used in the manufacturing process across different industries.

An experienced operator usually uses a specialized machine tool to program a set of operations according to your part design.

The control system of the CNC machine allows the tool to perform the set operations and movements so that the final parts can meet your specific requirements.

The CNC machining cost depends on many factors and varies among different situations.

The material is a big factor. The machining difficulties can vary greatly depending on the materials you choose, which will affect the CNC machining cost.

The design complexity also makes a difference in the CNC machining cost.

It’s easy to understand that the more complex the design is, the more machining process is required and the higher the price will be.

Other factors such as market fluctuation and the order quantity can also affect the final quotation.

If you want to know the CNC machining cost for your project, send us a message and you will receive a quotation with manufacturing advice within 24 hours.

There is a wide range of CNC machining services. YIJIN Hardware covers the most popular types that can support most of your CNC machining designs and projects, including the following:

- CNC Turning Services

- CNC Milling Services

- CNC Boring Services

- CNC Drilling Services

Other precision CNC machining services are also available on demand. Contact us to discuss details and get an instant quote.

CNC machining center is basically an automated machine tool with a programmed control system.

Based on the position of the spindle, CNC machining centers can be divided into vertical, horizontal, gantry, and universal types.

Vertical CNC Machining Center:

The vertical CNC machining center usually adopts the column structure in fixed positions and a rectangular worktable.

There are usually three linear motion coordinates (X, Y, and Z axes) on the worktable although a fourth axis (A) can also be installed.

The vertical CNC machining center has a compact and simple structure with a lower price tag.

It’s easy to operate, observe the operations during the machining process, and debug the program if anything goes wrong.

This type of machining center is suitable for creating plates, sleeves, and plate parts.

However, the large parts with tall height can not be handled with a vertical CNC machining center due to the column’s height restrictions and its tool change mechanism.

Horizontal CNC Machining Center:

The horizontal CNC machining center adopts movable columns and the headstock between the two columns moves up and down along the guide rail during the manufacturing process.

There are usually three motion directions: Axis X moves between the left and right sides, axis Z moves between front and back, and axis Z moves between the up and down.

A fourth axis A can also be installed on the worktable just like the vertical CNC machining center.

The horizontal CNC machining center is often used for manufacturing spiral wires and cylindrical cams.

It’s not that easy to observe the debug program, test the pin cutting, monitor the manufacturing process, and clamp and measure parts.

However, it’s easy to discharge pins during the process.

Compared with the vertical CNC machining center, the horizontal types feature a more complicated structure that takes up larger space and leads to a higher price.

Gantry CNC Machining Center:

In most cases, the gantry CNC machining center features a vertical spindle, an ATC system and replaceable spindle head accessories.

The system is very functional and can be used for multiple purposes with a single machine.

This type of CNC machining center is suitable for parts of large sizes.

Universal CNC Machining Center:

The universal CNC machining center is a five-sided machining center. It features the functions of both the vertical and horizontal CNC machining center types.

When a workpiece is clamped, all sides, excluding the mounting surface, can be completed at one time.

There are basically two types of universal CNC machining centers:

1) The one that can work as a vertical or horizontal CNC machining center with the spindle being able to rotate 90°

2) The worktable rotates 90° with the workpiece and the spindle remains in the same direction

Choosing a reliable CNC machining manufacturer is crucial to get high-quality parts as desired.

There are several things you need to take into consideration when searching for the best CNC machining service provider:

1. Reputation

A good reputation means the CNC machining company is striving for customer satisfaction with quality products and after-sales service.

Always check out the comments from its previous customers to decide whether to work with the CNC machining service provider.

2. Product Quality

The quality of CNC machining parts is the top consideration for your purchase.

A reliable CNC machining manufacturer should listen to customers’ voices and produce the parts strictly according to the client’s requirements.

At YIJIN Hardware, you can even configure the models and the guide rails to meet your specific accuracy requirements.

3. After-Sales Service

Good after-sales service doesn’t mean the products are problematic. It shows that the CNC machining manufacturer is reliable, so you can always find support if anything goes wrong.

YIJIN Hardware has a very efficient and professional after-sales team that handles your issues in a timely manner.

Besides that, a follow-up is carried out after purchase and service to make sure you are satisfied with the CNC machining parts.

4. Qualitifications & Certifications

There are a lot of CNC machining manufacturers on the Internet and the information can be dazzling.

Be sure to check out their qualifications and certifications (preferably revealed by third parties) before you place the order.

If you are shopping online, pay attention to the store’s rate, customer reviews, and the age of the store, which greatly reflects whether the CNC machining supplier can be trusted or not.

Choosing a satisfying CNC machining service provider requires extensive research and comparison.

If it’s possible, you can make a field trip to select the best company for your project.

We offer fast and cost-effective CNC machining solutions.

Get high-quality parts for your CNC machining projects with fast turnaround times, following your design specifications.